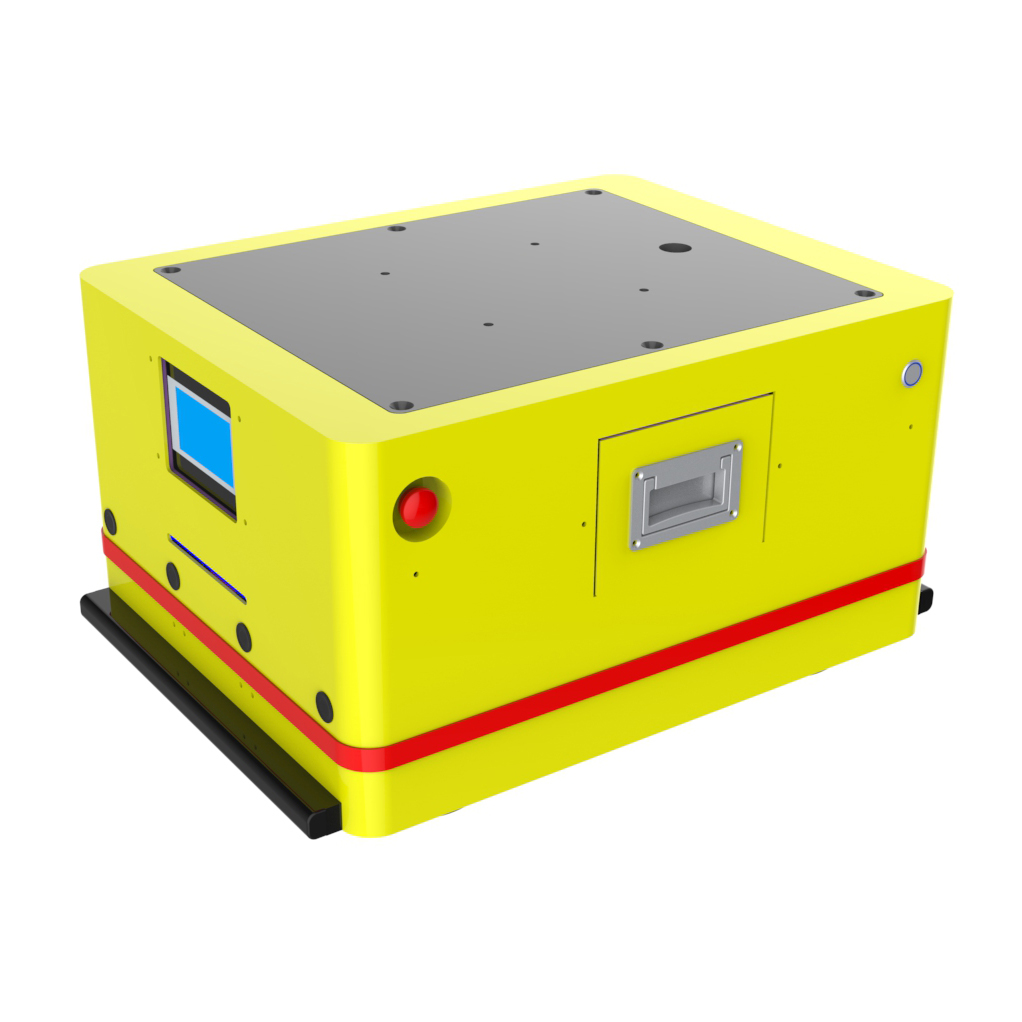

Both direction backpack amr autonomous mobile robots are designed to be capable of moving in both directions. This is a great feature to have when working in a warehouse or other type of facility where the robot needs to be able to move from one side of the room to another or back again. This is also beneficial if there are obstacles that need to be avoided when moving from one area to another.

Both direction backpack amr autonomous mobile robots is a company that has been providing both direction backpack amr autonomous mobile robots,amr warehouse,amr autonomous mobile robots,and amr warehouse automation services since 2016. Their goal is to help their clients stay on top of the latest developments in both direction backpack amr autonomous mobile robots technology and to provide them with the best possible solutions in this field. They offer a wide range of both direction backpack amr autonomous mobile robots products, including:

Both-direction backpack AMRs are autonomous mobile robots that can be used in warehouses. They are designed to move around the warehouse and pick up items that have been placed in certain areas, or to put them back where they belong. The AMR has two arms, each with a gripper, so it can grasp items of various shapes and sizes.

The AMR can be programmed to go to a specific area of the warehouse and perform tasks such as picking up items from a shelf and placing them in another area or returning them to their original location. It can also be programmed to perform more complicated tasks such as finding products on an assembly line and putting them into boxes for shipping.

Ø Single-drive bidirectional operation, capable of forward, backward, 90 °/180 °/360 ° rotation, acceleration, deceleration, bifurcated turning, timed stop, reversing operation and other multi-function driving;

Ø Ø The top of AGV can directly place materials or carry material frame, roller platform, etc., automatically operate the distribution line materials, efficiently realize the turnover of workshop materials, and maximize the production efficiency of the enterprise;

Ø Ø Multi-sensor integrated navigation is safe and reliable, flexible and efficient, realizes full automation without manual intervention, reduces manual labor intensity through automatic handling, seamlessly interfaces MES/WMS/ERP system through intelligent scheduling, improves logistics efficiency, quickly and flexibly adapts to different complex scenarios, and efficiently completes the automatic transportation of logistics.

performance parameter | description |

Model number | VL-BF-300SX-001 |

Overall dimension | StandardL895mm*W600mm*H300mm(Customized) |

Navigation type | Magnetic navigation |

Driving form | Differential drive |

Running direction | Multi-functional driving such as forward, backward, reverse, bifurcated turn, timed stop, reversing operation, etc |

Speed | 0~40m/min(Customized) |

Max Load | 100KG(Customized) |

Gradeability | ≤2Degree |

Turning radius | 500mmOr in situ90°/180°/360°revolve |

Stop precision | ±10mm |

Navigation accuracy | ±10mm |

Duration | 8-12H(Customized) |

Charging mode | Manual charging/automatic charging (optional) |

human-computer interaction | 4.3Inch touch screen |

Types of alarm | Audible and visual alarm |

Communication network | WIFINetwork/RF network |

Power battery | 40AhHigh quality lithium battery |

Protection rate | Obstacle sensor+contact bumper+emergency stop button |

Design life | >80000H |

Contact: Bill wang

Phone: +8618664066083

E-mail: info@vibootech.com

Whatsapp:+8618664066083

Add: No.23, Machong Avenue, Machong Town, Dongguan City, Guangdong Province China.

We chat